Siemtcoat® Silicone Release Coating

Topwin, a subsidiary of Wynca Group, specializes in manufacturing silicone-based functional products and stands out as a distinguished technical service provider.

Siemtcoat® serves as an efficacious agent helping the adhesive release easier from the backing materials (paper, film, other substrates) . The users can select the optimal product for their specific application or intended purpose from our line of products, which includes solventless, solvent-based, emulsion formulations. Silicone Release Coating systems consist of base polymer, crosslinker, catalyst and other additives. Widely used in label stock, envelopes, diversified tapes, bakery paper and foodstuff package, commercial graphics art, security signage and outdoor advertising, hygienic application such as baby diaper, feminine hygiene and adult incontience products, industry application for roof coverings, pipe and thermal insulation, medical application for body electrodes, adhesive bandages, wound dressings, surgical covers, ECG, etc.

Topwin's Siemtcoat® silicone release coating systems consist of four basic components: base polymer, crosslinker, catalyst and various additives. These components can be combined in numerous ways to create customized formulations, which can be tailored to your needs through consultation with our technical teams.

Solvent Silicone Release Coating

| Items | Product Grades |

Silicone Active Ingredient (%) |

Typical Viscosity (25℃,mPa.s) |

Substrate | Release Force (Tesa7475, g/25mm) | Subsequent Adhesion (%,Nitto 31B) |

Key Features | Packaging |

|

Thermal Cure, |

Siemtcoat® SC5210 | 30 | 7000 | Paper | 5-20 | 80-85 | General purpose, Light release force | 1000Kg/IBC Drum; 180Kg/Iron Drum. |

| Siemtcoat® SC5511 | 30 | 11000 | Paper | 5-15 | 83-87 | Stable release force, High subsequent adhesion, Suitable for various substrates | 1000Kg/IBC Drum; 180Kg/Iron Drum. |

|

| Siemtcoat® SC5512 | 30 | 9000 | PET, PP, PE Film |

5-15 | 83-87 | High subsequent adhesion, Stable peel force | 1000Kg/IBC Drum; 180Kg/Iron Drum. |

|

| Siemtcoat® SC5516 | 30 | 9000 | PE Film | 5-15 | 75-83 | Light release force, Low temperature cure, Suitable for various substrates | 1000Kg/IBC Drum; 180Kg/Iron Drum. |

|

| Siemtcoat® SC5532 | 30 | 13000 | PE Film, OPP Tape |

15-25 | 75-83 | Low temperature cure, High subsequent adhesion, Good anchorage performance | 1000Kg/IBC Drum; 180Kg/Iron Drum. |

Remark

. Solvent type silicones have a limited usage due to solvent problem.

. Solvent type silicones are dangerous cargos and needed to be shipped as dangerous shipment.

Solventless Silicone Release Coating

| Items | Product Grades |

Silicone Active Ingredient (%) |

Typical Viscosity (25℃,㎟/s) |

Substrate | Release Force (Tesa7475, g/25mm) |

Subsequent Adhesion (%,Nitto 31B) |

Key Features | Packaging |

| Thermal Cure, Solventless |

Siemtcoat® SF300 | 100 | 350 | Paper | 5-15 | 90-95 | General purpose, Stable peeling force, Suitable to sensitive adhesives | 1000Kg/IBC Drum; 180Kg/Iron Drum. |

| Siemtcoat® SF300H | 100 | 350 | Paper | 5-15 | 90-95 | Stable release force, Good anchorage performance, Suitable for double-sided PE coated paper | 1000Kg/IBC Drum; 180Kg/Iron Drum. |

|

| Siemtcoat® SF180MR | 100 | 240 | Paper | 5-20 | 90-95 | Flatter release profile, Low misting with high speed | 1000Kg/IBC Drum; 180Kg/ Iron Drum. |

|

| Siemtcoat® SF190MR | 100 | 300 | Paper | 5-20 | 90-95 | Flatter release profile, Low misting with medium or high speed | 1000Kg/IBC Drum; 180Kg/Iron Drum. |

|

| Siemtcoat® SF500MR | 100 | 300 | Paper | 5-20 | 90-95 | Flatter release profile, Low misting with high speed | 1000Kg/IBC Drum; 180Kg/Iron Drum. |

|

| Siemtcoat® SF501 | 100 | 350 | Paper | 10-20 | 90-95 | Stable release force, Good anchorage performance, Suitable for doubled-sided PE coated paper | 1000Kg/IBC Drum; 180Kg/Iron Drum. |

|

| Siemtcoat® SF211 | 100 | 350 | Paper | 3-5 | 80-85 | Ultra-low release force | 1000Kg/IBC Drum; 180Kg/Iron Drum. |

|

| Siemtcoat® SF311 | 100 | 500 | MG Paper | 10-20 | 90-95 | Low temperature cure, Low and stable release force | 1000Kg/IBC Drum; 180Kg/Iron Drum. |

|

| Siemtcoat® SF311MR | 100 | 500 | Low-cost Paper | 10-20 | 90-95 | Fast Cure, low misting with high speed | 1000Kg/IBC Drum; 180Kg/Iron Drum. |

|

| Siemtcoat® SF363 | 100 | 350 | Paper | 5-15 | 90-95 | Fast cure, Low platinum and Cost effective | 1000Kg/IBC Drum; 180Kg/Iron Drum. |

|

| Siemtcoat® SF370 | 100 | 460 | PET Flim | 5-15 | 90-95 | Premium release force, Good anchorage performance specially for PET | 1000Kg/IBC Drum; 180Kg/Iron Drum. |

| Items | Product Grades |

Silicone Active Ingredient (%) |

Typical Viscosity (25℃,mPa.s) |

Substrate | Release Force (Tesa7475, g/25mm) |

Subsequent Adhesion (%,Nitto 31B) |

Key Features | Packaging |

| Thermal Cure, Emulsion |

Siemtcoat® EM5502 | 40 | 200 | Paper | 5-15 | 85-90 | Suitable for paper coating, used in food & sanitary materials, etc. | 950Kg/IBC Drum; 180Kg/Plastic Drum. |

| Siemtcoat® EM5503 | 40 | 200 | PET Film | 5-15 | 85-90 | Suitable for in-line and off-line coating of PET film, with good anchorage performance | 950Kg/IBC Drum; 180Kg/Plastic Drum. |

Remark

. Emulsion type silicones should be agitated thoroughly before use.

. Emulsion type silicones may freeze at low temperatures, so users in colder regions should take special care with regard to storage.

. Emulsion type silicones should be storage in a closed container at +10°C to +30°C temperature.

Crosslinker,Catalyst and Additives

|

Items |

Grades |

Typical Viscosity

(25℃,㎟/s) |

Release Force |

Substrate | Key Features | Packaging |

| Crosslinker | Siemtcoat® 8066 | 60 | Low | Paper | Fast cure | 20Kg/Plastic Drum; 1Kg/Plastic Bottle |

| Siemtcoat® 8118 | 40 | Low | Paper | Fast cure, Well-adapted | 20Kg/Plastic Drum; 1Kg/Plastic Bottle |

|

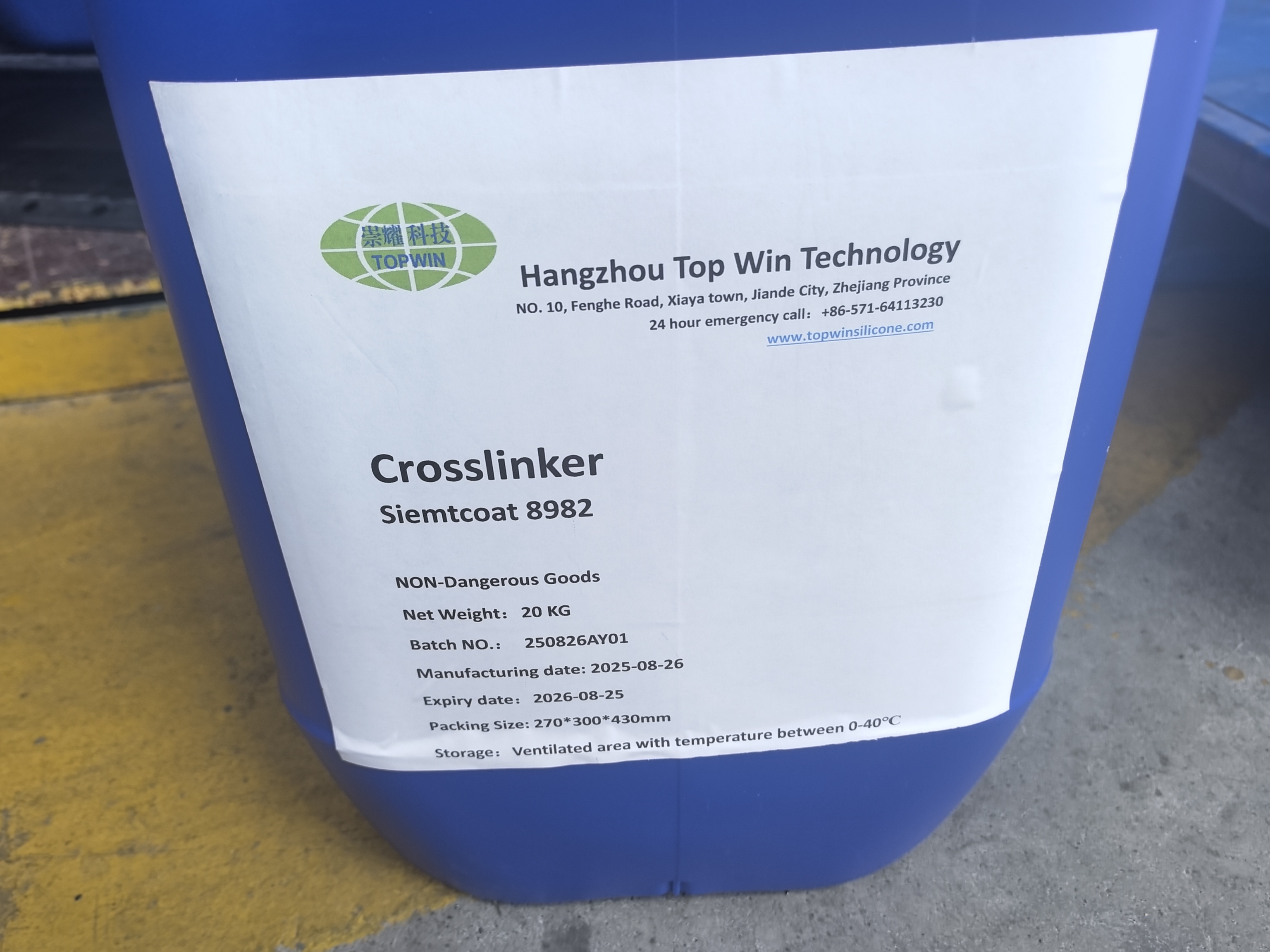

| Siemtcoat® 8982 | 35 | Low | Paper/PEK/Film | General product, Well-adapted with improved anchorage | 20Kg/Plastic Drum; 1Kg/Plastic Bottle |

|

| Siemtcoat® 8983 | 30 | Low | Paper/PEK/Film | General product,good balance of cure speed and anchorage |

20Kg/Plastic Drum; 1Kg/Plastic Bottle |

|

| Siemtcoat® 8984 | 30 | Low | Paper/PEK/Film | Good anchorage performance | 20Kg/Plastic Drum; 1Kg/Plastic Bottle |

|

| Siemtcoat® 8158 | 20 | Low | Paper/PEK/Film | Excellent anchorage performance | 20Kg/Plastic Drum; 1Kg/Plastic Bottle |

|

| Catalyst | Siemtcoat® 5000 | 40 | - | Paper/PEK/Film | High platinum content | 20Kg/Plastic Drum; 1Kg/Plastic Bottle |

| Siemtcoat® 3000 | 40 | - | Paper/PEK/Film | Medium platinum content, Long bath life | 20Kg/Plastic Drum; 1Kg/Plastic Bottle |

|

| Siemtcoat® 1500 | 40 | - | Paper/PEK/Film | Low platinum content | 20Kg/Plastic Drum; 1Kg/Plastic Bottle |

|

| Siemtcoat® 5509 | 200 | - | Paper/PEK/Film | Catalyst for Emuslion | 20Kg/Plastic Drum; 1Kg/Plastic Bottle |

|

| Control Release Additive | Siemtcoat® LRA-2 | 300 | Premium | Paper/PEK/Film | Low release additive | 20Kg/Plastic Drum; 1Kg/Plastic Bottle |

| Siemtcoat® LRA-3 | 500 | Premium | Paper/PEK/Film | High efficiency low release force additive | 20Kg/Plastic Drum; 1Kg/Plastic Bottle |

|

| Siemtcoat® HRA-11T | 20 | Tight | Paper/PEK/Film | High release additive, Additive for Solvent | 20Kg/Plastic Drum; 1Kg/Plastic Bottle |

|

| Siemtcoat® HRA-10F | 380 | Tight | Paper/PEK/Film | High release additive | 20Kg/Plastic Drum; 1Kg/Plastic Bottle |

|

| Siemtcoat® HRA-11F | 1000 | Tight | Paper/PEK/Film | High efficiency tight release additive | 20Kg/Plastic Drum; 1Kg/Plastic Bottle |

|

| Anchorage Additive | Siemtcoat® ADD5176 | 15 | - | Paper/PEK/Film | Anchorage improvement additive | 20Kg/Plastic Drum; 1Kg/Plastic Bottle |

| Siemtcoat® ADD5108 | 7 | - | Film | Anchorage improvement additive for Emuslion | 20Kg/Plastic Drum; 1Kg/Plastic Bottle |

Note:

1. Typical properties are not to be used as or to develop specifications.

2. For more product information,please visit our website: Http://www.topwinsilicone.com/ or contact our sales and technical representatives.

3. For detailed test conditions, please refer to product technical data sheet(TDS).

4. Siemtcoat® is Topwin company's trademark, all rights reserved.

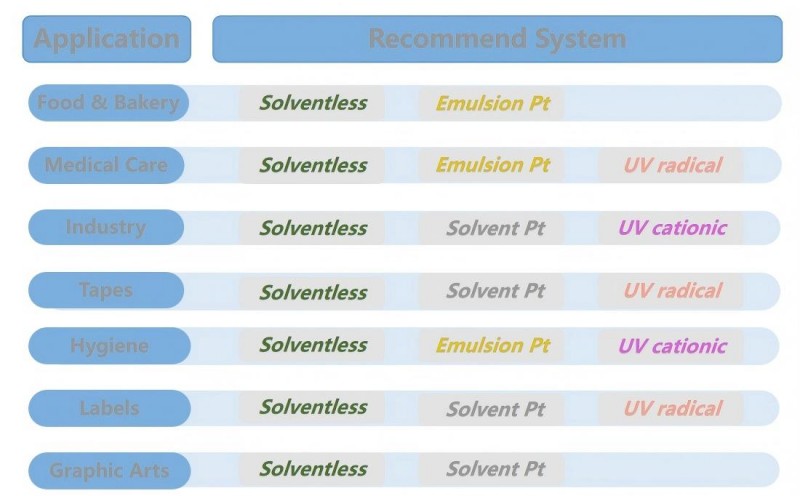

Applications & Recommend System

Siemtcoat® SF311MR

Siemtcoat® SF311MR

Siemtcoat® 8118

Siemtcoat®8118

Siemtcoat® 8118

Siemtcoat®8118

Siemtcoat® 8982

Siemtcoat®8982

Siemtcoat® 8982

Siemtcoat®8982

Siemtcoat® SF190MR

SF190MR

Siemtcoat® SF190MR

SF190MR