What are Release Liners?

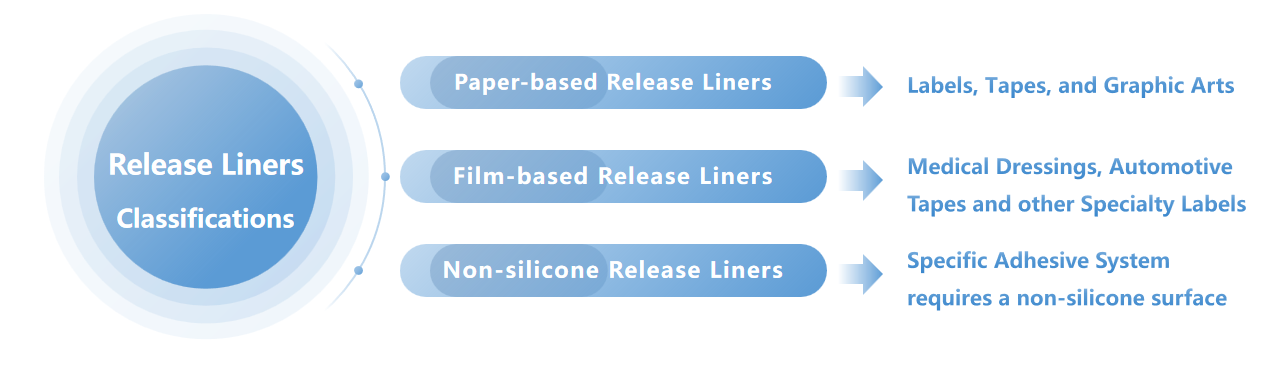

A release liner is a material that provides a temporary protective barrier between adhesive materials and their backing, preventing them from sticking to each other. It is typically made of paper or film, and a release coating is applied to one or both sides to create a non-stick surface.

Release liners are commonly used in various industries where adhesive products are involved. They serve as a barrier between the adhesive and the product, ensuring that the adhesive remains intact and ready for use. Without release liners, adhesive-coated products would become unusable due to sticking together, causing inconvenience and potential damage.

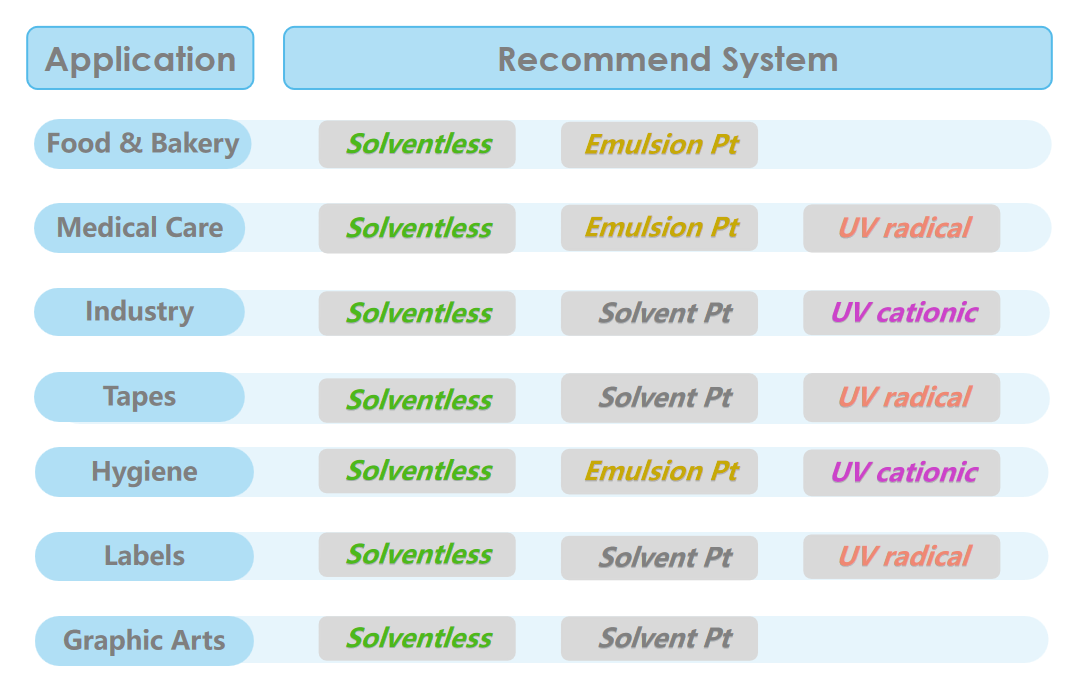

Regarding the manufacturing process of release liners, different methods are employed depending on the desired characteristics and applications. The release coating can be applied through various techniques such as Solvent-based, Solventless, and Emulsion by Thermal Curing or UV Curing. Each method has its advantages and is chosen based on factors like cost, performance requirements, and environmental considerations.

Labeling: In the labeling industry, release liners carry self-adhesive labels until they are applied to products.

Medical: In medical applications, they are used in products like bandages, wound dressings, and diagnostic devices.

Graphics and Signage: Release liners are used in the production of self-adhesive graphics, decals, and signage materials.

Tapes: Adhesive tapes for various industrial and consumer applications use release liners to protect and manage the adhesive surface.

Construction: They are used in self-adhesive building materials, such as waterproofing membranes and insulation materials.

Recommend System of Silicone Release Coating

Innovations in materials and coatings have led to the development of more efficient and sustainable release liners. For example, there are efforts to create liners with improved recyclability and reduced environmental impact, as well as liners with enhanced performance characteristics for specific applications.

Overall, release liners play a vital role in the functionality and performance of self-adhesive materials across many industries.