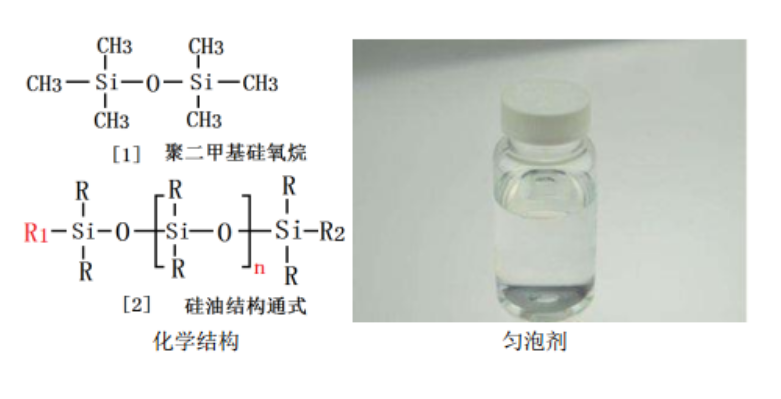

Silicone stabilizer is an essential part and plays an important role in polyurethane rigid foam. PU rigid foam is formed by the interaction of Isocyanate and polyether polyols with various additives such as silicone oils, catalysts and blowing agents, etc. Polyurethane rigid foam is a thermal insulation material with excellent thermal insulation performance, most of the cell structure is closed-cell type, which is inseparable from the role of silicone surfactant/stabilizer/additive.

Silicone stabilizer:(also named as silicone/silicone surfactant/additive). It improves the compatibility of component-emulsifying foam materials, stabilizing foam, and controlling cell size. PU rigid foam can be used in wide application fields, such as home appliance insulation, pipe insulation panels, spray foam, spraying and pipe, solar energy, wood imitation, OCF, etc. With the increasing requirements of environmental regulations and energy standards of household appliances, the requirements for polyurethane rigid foam in refrigerators are gradually increasing, and better thermal conductivity and lower energy consumption levels will be more popular in the market. High-end home appliance refrigerators need extremely high-quality silicone, which needs strong nucleation ability, low K factor, and few surface bubbles. TOP WIN developed a product#XH-1625 that can meet the requirements, it’s suitable for high-end refrigerators/freezers with C5, HFC, HFO, or co-blown systems, and also provides low K factor.

Key features: low K factor, good nucleation ability, good emulsification ability, excellent foam ability, dimensional stability, and reduction of surface defects.

TOP WIN also produces many different kinds of silicone products suitable for different industries: Silicone surfactants for PU foam, silicone for PU shoe sole/footwear, silicone release coating for paper and film, silicone additives for textile and leather, silicone additives for coating, silicone polyether for agriculture.