Tips for Selecting the Right Release Paper

Release liner, also known as release paper, is a paper-based or plastic-based film sheet used during production to prevent adhesive surfaces from sticking too quickly. One or both sides of it are coated with a release agent, which provides a release effect for any sticky materials, such as adhesives or mastic.

Release liners come in a variety of colors, with or without printing on the front, rear, or under the low surface energy coating. Release is the act of separating a liner from something sticky; the liner serves as the vehicle for the release agent.

To ensure that the release paper works as expected and provides the best results, it is crucial to choose a release paper that is suitable for your specific application.

Here are some tips for selecting the right release paper and using and storing it properly:

- Identify the specific applications and requirements:

The first step is to identify the specific applications and requirements for the release paper. Factors to consider include the type of adhesive, the surface it will be applied to, the temperature range, and the desired release properties.

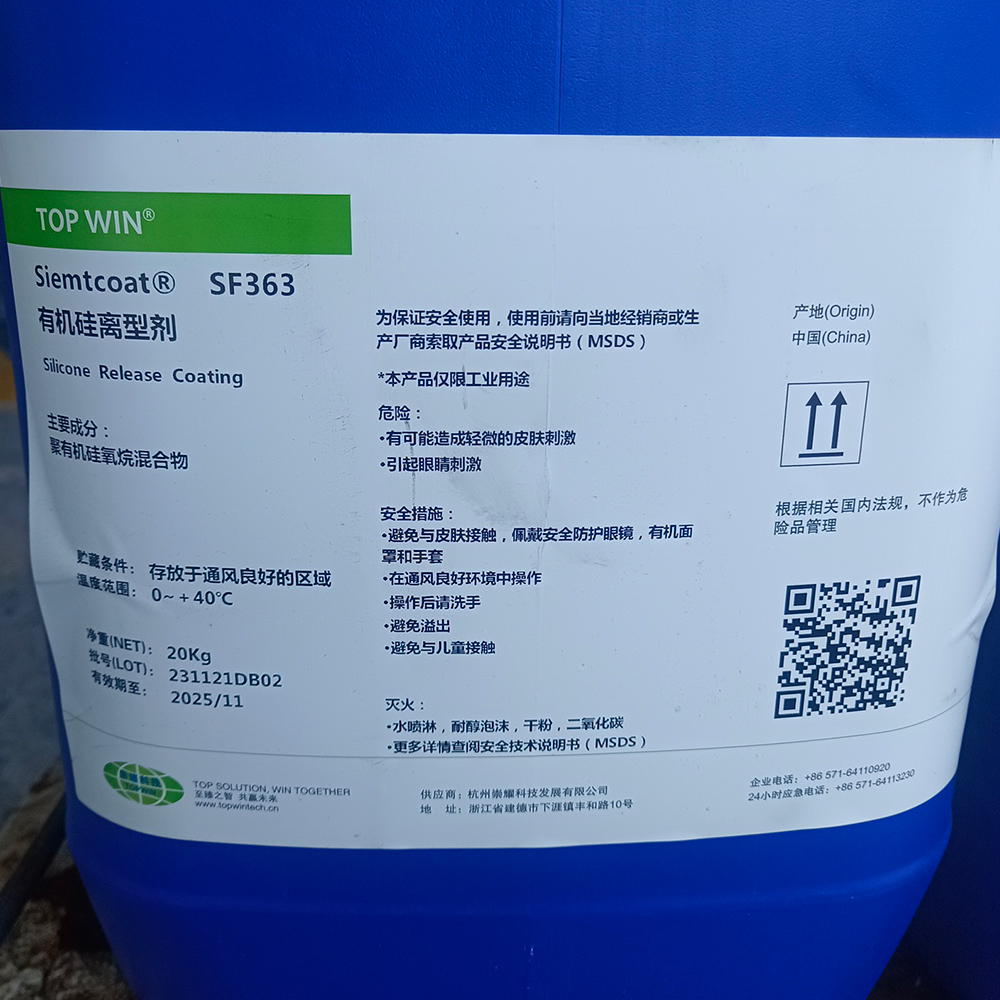

- Consider the type of release coating:

Different release papers have different release coatings, such as silicone, wax, or polyethylene (PE). Each coating has its own advantages and disadvantages and is suitable for different applications. For example, silicone-coated release papers are suitable for adhesives with high-temperature resistance and high cohesive strength, while wax-coated release papers are ideal for adhesives with low-temperature resistance and low cohesive strength.

- Consider the thickness and weight of the release paper:

The thickness and weight of the release paper affect its strength and handling performance. Thicker release papers are typically stronger and more durable, but it may be more difficult to handle.

- Look for additional features:

Some release papers are pre-cut slits, perforated, or printed grids for easy alignment. Consider whether your application requires these features.

- Proper Storage of Release Paper:

Release paper should be stored in a cool, dry, and dust-free environment. Exposure to direct sunlight, heat, and moisture should also be prevented to avoid degradation of the release coating.

Once you have selected the appropriate release liner for your application, it is equally important to use it properly to ensure the best results.

It’s important to use the right amount of adhesive, apply it to the right surface, and allow it to cure properly to ensure a strong bond.

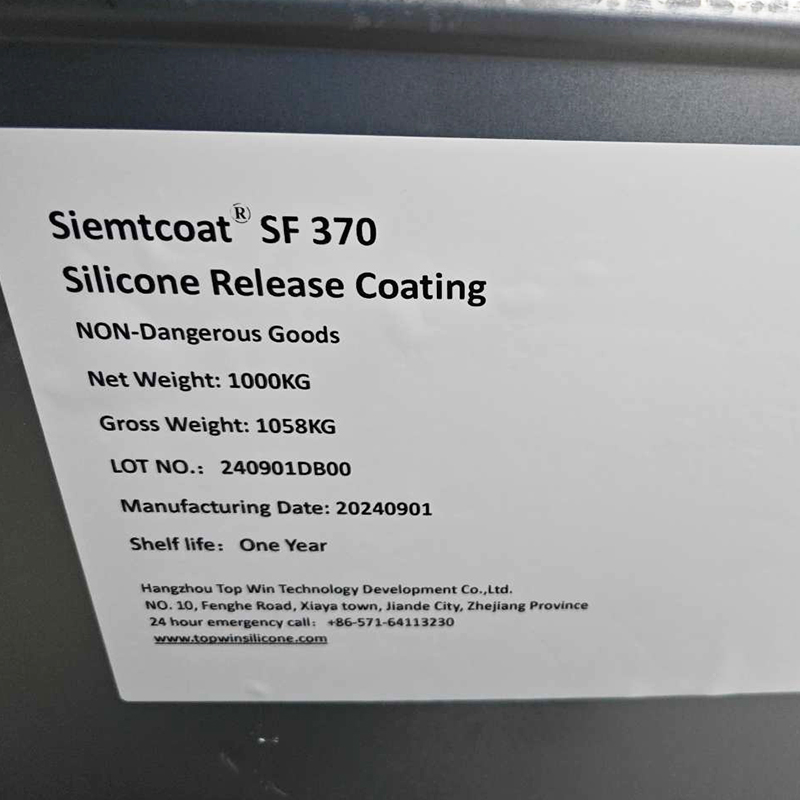

TopWin is one of the leading & professional manufacturers with more than 20 years of experience and has domestic top-level engineers in the silicone surfactant industry. We specialize in producing all kinds of SILICONE-based new materials and specialize in research, production, sales, and marketing of silicone-based performance materials. Provide good OEM&ODM service. Our products are mainly used in polyurethane foam, Agriculture, Coatings and Inks, Leather & Textiles, Film and Paper, Cosmetic industry, etc.